Grey color RTV silicone sealant 310ml/cartridge, equal to Loctite 5699. Low viscosity and excellent adhesion to oil surfaces. Suitable for sealing joint surface of all kinds machineries.

Characteristics:

Physical Properties:

Applications:

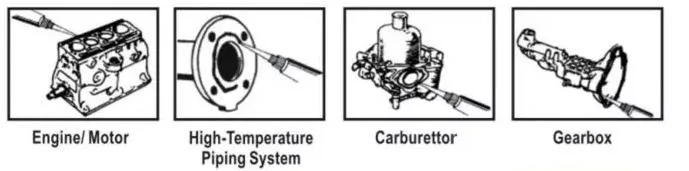

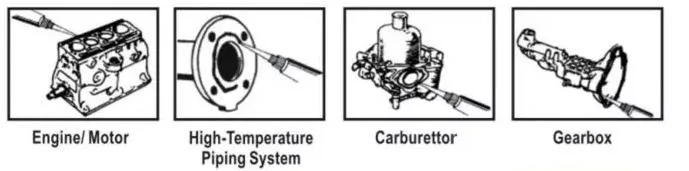

Sealing and anti-shaking of engines, valve cages, bonnets and other mechanical parts in cars, motorcycles, farming machines, also, seal in high-temp fields, like in machinery, electronic, chemicals, and hardware, etc.

User's Guide:

1. Clean all surfaces thoroughly. Remove old gaskets and prepare flange surfaces. Dry and remove all oil and grease

2. Remove the cap, puncture inner seal of the tube, screw on nozzle with a desired size

3. Apply continuous, uniform 1~4mm bead around perimeter of one surface. or completely surround all bolt holes

4. Wait about 10 minutes for glue to skin over. Then reassemble the parts

5. Gasket maker dries to touch in 1 hour and allow to bond after 24 hour fully curing.

Notes:

1. Clean the assembled parts by removing the oil and grease.

2. it will release some acid odor when assemble the parts, so using in an adequate ventilated place.

3. Screw the nozzle tightly after using in order to avoid its curing inside the tube

4.Keep away from children.

OEM service is highly welcome, we can help customer design drawing and printing.

Characteristics:

1, RTV,low odor, non-corrosive, low volatility.

2, Resistant to most chemicals and solvents ,black.

3, For sealing combustion engine.

Physical Properties:

Color: | Grey |

Specific gravity: | 1.18g/cm³ |

Tensile strength(GB/T528): | 2.0MPa(Room temperature) |

Elongation at break(GB/T528): | 260% |

Tack free time: | 10~20min |

Curing depth: | ≥2mm(24h) |

Temperature range: | -54~260ºC |

Applications:

Sealing and anti-shaking of engines, valve cages, bonnets and other mechanical parts in cars, motorcycles, farming machines, also, seal in high-temp fields, like in machinery, electronic, chemicals, and hardware, etc.

User's Guide:

1. Clean all surfaces thoroughly. Remove old gaskets and prepare flange surfaces. Dry and remove all oil and grease

2. Remove the cap, puncture inner seal of the tube, screw on nozzle with a desired size

3. Apply continuous, uniform 1~4mm bead around perimeter of one surface. or completely surround all bolt holes

4. Wait about 10 minutes for glue to skin over. Then reassemble the parts

5. Gasket maker dries to touch in 1 hour and allow to bond after 24 hour fully curing.

Notes:

1. Clean the assembled parts by removing the oil and grease.

2. it will release some acid odor when assemble the parts, so using in an adequate ventilated place.

3. Screw the nozzle tightly after using in order to avoid its curing inside the tube

4.Keep away from children.

OEM service is highly welcome, we can help customer design drawing and printing.