Red Silicone Excellent Compression Set Rubber U Shaped Ring

Material Description for Rubber U Shaped Ring

| Material | SIL(Silicone Rubber) |

| Advantage | 1,Excellent Rebound Resistance |

| 2,Excellent Oxygen and Ozone Resistance | |

| 3,Excellent Weathering and Heat Resistance | |

| 4,Excellent Heat and Low Temperature Resistance | |

| 5,Good heat insulation and heat dissipation. | |

| 6,Good electrical insulation | |

| Disadvantage | 1,Poor Aliphatic-solvent Resistance |

| 2,Poor Alkaline Resistance | |

| Temperature | -40ºC-220ºC, -100ºC-250ºC(special formula) |

| Application | 1,the household appliances industry seal or rubber parts, such as electric kettle, electric irons, microwave oven rubber parts. |

2The electronics industry seal or rubber parts, such as mobile phone keys, shock pad DVD, cable joint seal etc. | |

3Contact with the human body on various types of products on the seal, such as water bottles, water dispensers |

How to choose appropriate Rubber U Shaped Ring?

1.Material

what kind of temperature environment Rubber U Ring will be used?

Rubber material temperature table

Rubber Materials | General ( °C) | Special( °C) |

| NBR | -40~120 | -50~150 |

| EPDM | -40~150 | -50~200 |

| SL | -40~220 | -100~250 |

| HNBR | -40~170 | -40~175 |

| ACM | -20~150 | -25~175 |

| SBR | -30~100 | -40~110 |

| FPM | -30~200 | -40~280 |

| CR | -40~100 | -50~150 |

| IIR | -50~100 | -60~130 |

| NR | -20~100 | |

| PU | -30~70 | -40~100 |

Or if there is any other requirements ,it should be taken in consideration.

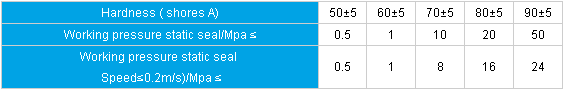

2.Hardness

The hardness for Rubber U Ring is relative with the working pressure

Relationship of hardness & working pressure:

3.Working condition

It`s important that keep the clean of working medium. Oil aging or pollution could make the components fail, accelerate the aging and abrasion of oil seal. Moreover the dirt could lead seal failure. Therefore, workers must be check the quality and cleanliness of oil regularly. Sealing parts are burn out by high temperature which caused by residual air compressed in oil of cylinder. In order to avoid it, in the initial operation of hydraulic system, exhaust air disposal is needed, hydraulic cylinder also should be work several minutes firstly under low pressure and slow running. Work normally after confirming that all of the air have be removed.

Our factory have different certificates, such as ISO9001, TS16949, FDA, RoHs & Reach etc.

Our Company

Dong Guan RuiChen Sealing Co.,Ltd.

The molding processes we use is Comprssion Molding:

Taking a pr-measured amount of raw rubber material that is placed into a heated open lower mold cavity.This method can produce custom rubber products that are curved,and is usually more cheap than other molding process.

We have thousands of rubber products ,standard or non-standard .

Process Flow:

Raw material test → Prescribe → Mixing Material → Cutting Material → First Cure → First Part Inspection → Casual Inspection → Burr Dealing → Eye Inspection → IPQC → Washing or Grinding → Post Cure → FQC → Packing

Packing & Delivery:

Packing: PE bag inside, Carton outside.

Carton size: 46cm*33cm*33cm, 51cm*33cm*33cm, 29cm*23cm*19cm

Delivery: Large quantity by ship, small quantity by air or express.

FAQ:

1,Are you manufacture or trading company ?

We are manufacture, we have two factories, one located in Shangrao City, Jiangxi Province, one in Dongguan City, Guangdong Province

2,Can I get samples from you ?

Of course, you can. If the samples you need we have in stock, you can get them for free,

only need to pay for the express cost.

3,What's the term of payment ?

Amount < US$2000, 100% paid in advance by paypal or T/T;

Amount >= US$2000, 30% paid in advance, 70% balance before shipment by T/T.

4,Can you produce OEM products ?

Yes, we can produce products by your drawing or samples.

5,What's your MOQ ?

If we have the products in stock , the quantity by your requirement, If we don't have them in stock:

NBR, SIL, SBR, EPDM, NR: 100 US$; PU, HNBR, FKM: 150 US$